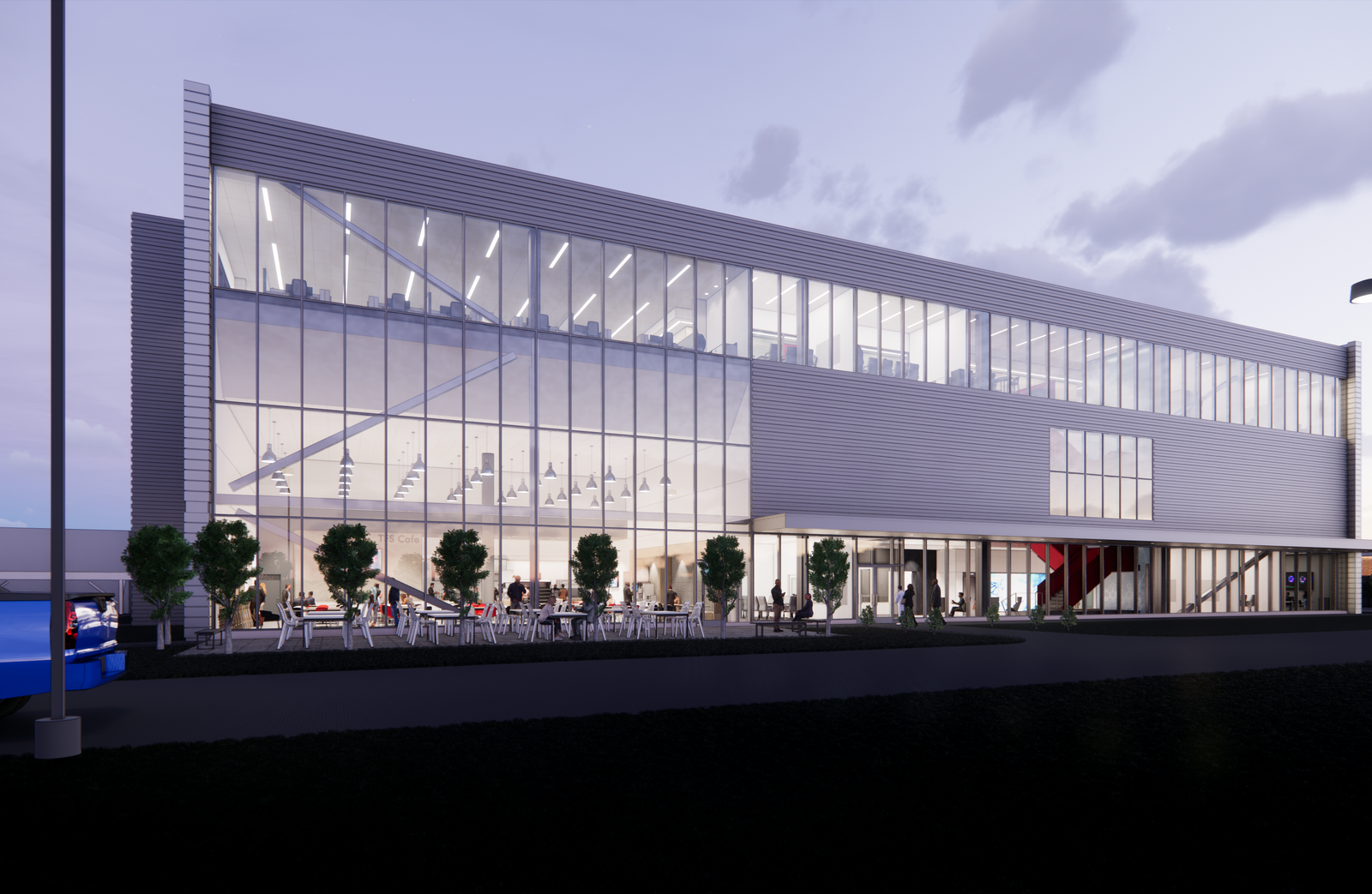

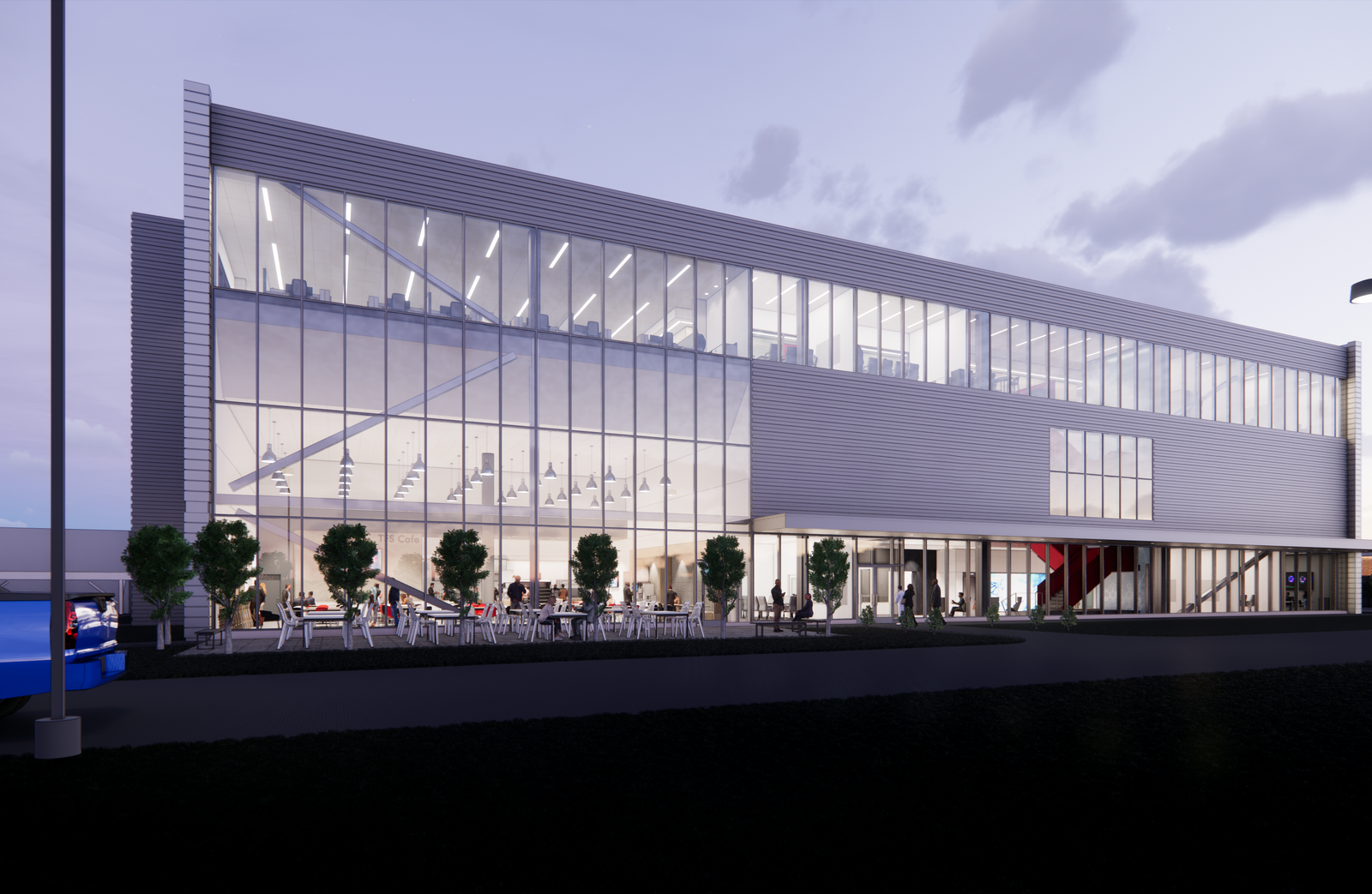

This project is a three story, 130,000 square feet pandemic site on the Client’s Greenville, NC campus under tight time constraints. The project consists of a greenfield building for incoming sampling/dispensing, two liquid vial filling lines, one AVI area, two future lyophilization area, compounding area, parts wash and autoclave area, cold rooms storage, an automated vial inspection line, lab area, cGMP warehouse, WIP storage, locker/gowning, administration, café, and mechanical/process support spaces. In addition to HVAC, dedicated systems for compressed air, chilled water, DI water, WFI systems, Clean Steam, Waste Handling, and

emergency power systems (UPS) are included in the scope. A mechanical floor and separate platform area over the top of the process areas house project specific mechanical and electrical equipment and some central plant utilities will be used to support this new space.

The intention of this project is to install a two new live virus, IMA Filling lines with isolators that are self-contained and segregated. These aseptic processing suites are designed for commercial use and provide flexible contract manufacturing to produce 150M doses over a 4-month production period based on a 10R vial containing 10 doses of 1mL assumed at 3.75M vials / month (37.5M doses / month). The timeline for the project was

accelerated in response to the COVID-19 pandemic.